A recent article in the Home Energy Magazine analyzes the embodied energy of different wall structures for Passive House construction in cold climates. Basically, it’s great to have super insulated homes, but home much extra energy does it take to build them? Said another way, how many years will it take before the embodied energy it took to build the walls becomes less than the energy those walls saved.

They compared the following wall structures

- TJI frame with blown-in fiberglass insulation, built in Urbana, Illinois.

- Insulating concrete form (ICF) with exterior expanded polystyrene (EPS), built in southern Wisconsin.

- Structural insulated panel (SIP) filled with urethane foam with an interior 2 x 4 wall filled with blown-in cellulose, built in Belfast, Maine.

- Advanced 2 x 12 stud framing filled with open-cell spray foam and insulated on the exterior with either EPS or vacuum insulated panels (VIPs), built in Bemidji, Minnesota.

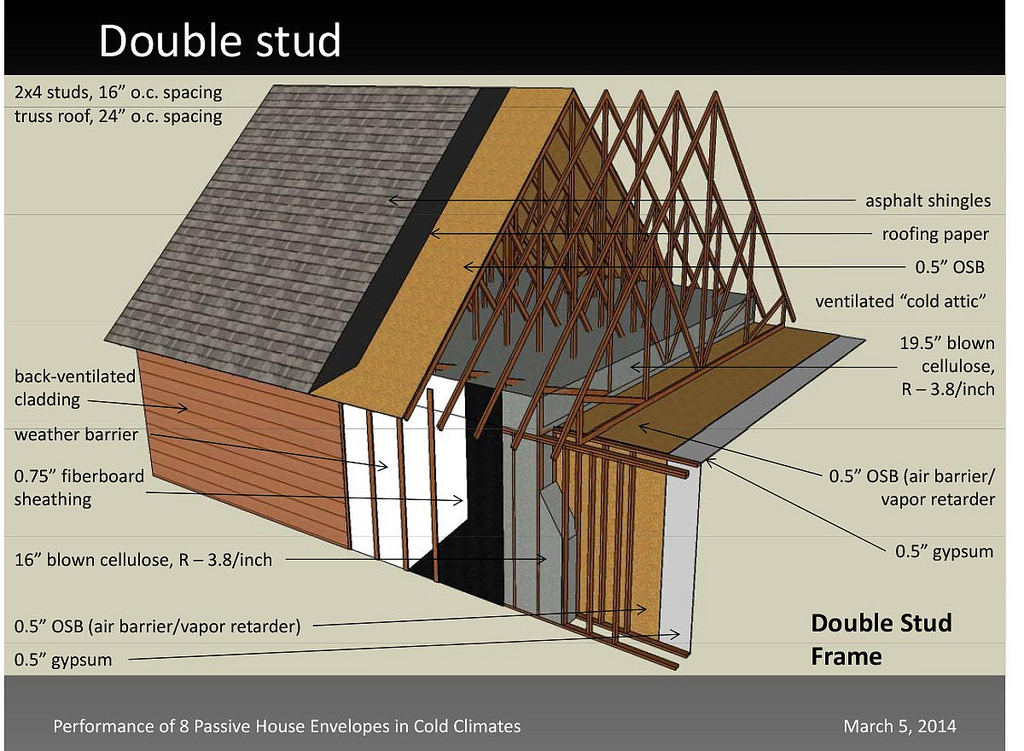

- Double 2 x 4 stud wall insulated with blown-in cellulose, built in Duluth, Minnesota.

The energy payback time for the wall assemblies ranged from immediately for the double-stud wall to 4.4 years for the mass wall—not a big chunk of a building’s expected lifetime. Because of the HFC blowing agent, the advanced frame with spray foam envelope has a carbon payback of 23 years.

Although the double-stud wall comes out smelling of roses in these comparisons, as long as you avoid specifying insulation made with an HFC blowing agent and minimize the use of energy-intensive materials, such as concrete and OSB, all of these envelopes would have a good energy and carbon payback.

Here is the double studd wall with cellulose:

As a New York Passive House builder the big question for me is how does this affect Passive Houses built in existing Brownstone buildings. The double stud and cellulose can easily be applied on the inside of the Brownstone brick walls. But there are two problems with this.

One problem is space. Brownstones cost a lot of money and to loose an extra several inches of floor space is a big deal.

The second problem is deterioration of the brick walls. Those brick walls have survived wonderfully for the past 100 years thanks to the nice warm heat from the building. Once you install the double stud walls you isolate the brick on the outside of the thermal envelope and the bricks are susceptible to freezing.

When the mortar in a brick wall freezes it expands. When it thaws it contracts. Over the years this wears away all the mortar and the wall falls apart. How long this takes is still a bit in the air since all Passive Houses in NYC and Brooklyn are only a couple years old.

One solution to both these issues is to build a less thick wall. You gain space and a little heat is lost to the outside, stopping the bricks from freezing. Clearly this is not ideal given the lost energy.

If anyone has solutions to these issues I am very interested to hear them.